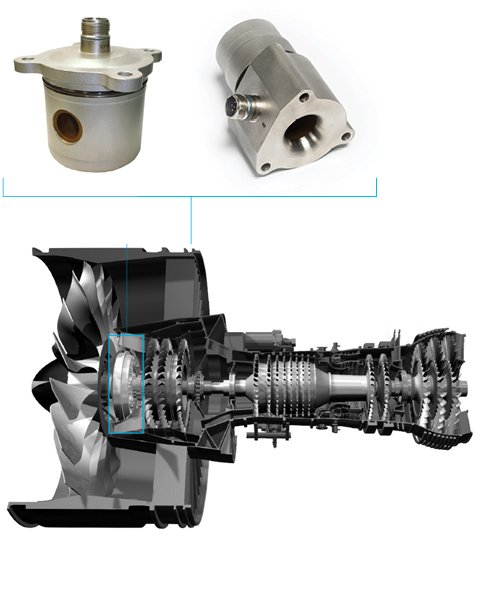

MetalSCAN for Aerospace

Real-time Prognostics

MetalSCAN is the alternative to notoriously unreliable chip detection systems which often fail to detect in-flight failures, unsafe operations, and mission abort events. Gastops originally developed MetalSCAN for the F-22 Advanced Tactical Fighter engine. Today, MetalSCAN is available for a wide range of military and commercial aircraft applications.

- Detect the onset of damage

- Measure health status

- Avoid in-flight failures and false indications

Proactive Detection of Service Needs

- Reduce maintenance and support costs

- Maximize mission readiness

- Improve reliability

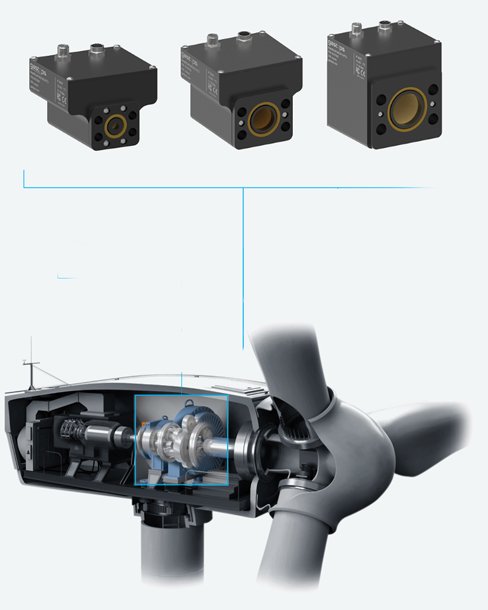

MetalSCAN for Wind Turbines

Reduce operating costs of wind energy production with critical component intelligence.

MetalSCAN technology empowers wind turbine operators to effectively manage gearbox health issues using oil debris monitoring.

Designed specifically for wind turbine platforms, the MetalSCAN MS3500 oil debris monitoring system provides continuous monitoring of the gearbox.

MetalSCAN is a full-flow, non-obstructive, online debris detection system installed in the gearbox lubrication system. It detects the onset of surface fatigue of bearings and gears and tracks the progressive deterioration of the damage in real time, providing a continuous measure of gearbox condition.

Featured installations:

Wind Energy:

- Bill of Materials on all Vestas, Siemens Gamesa, GE and Nordex turbines

- A Standard Option on all new Vestas (non EnVentusTM), Siemens Gamesa, Nordex Group and GE wind turbines

- Major gearbox manufacturers including ZF, Winergy, Bosch Rexroth, Eickhoff, NGC and Moventas

- Turbine owners/operators including ENGIE, Orsted, Vattenfall, Statkraft, E.ON, EDP Renewables, Brookfield, Boralex, RWE AG and Iberdrola

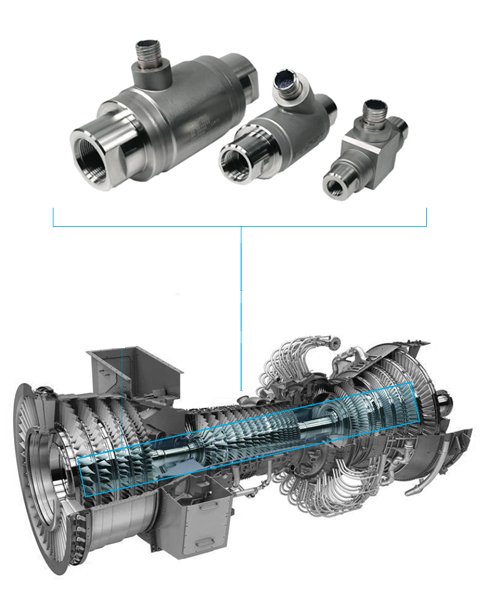

MetalSCAN for Power, Compression and Marine Propulsion

Real-time damage detection. Anytime. Anywhere. MetalSCAN MS4000/MS4110 oil debris monitoring systems provide condition monitoring in the energy, industrial, and marine industries. They detect and analyze metallic particles generated from rotating equipment due to bearing and gear wear.

MetalSCAN MS4000/MS4110 are online oil debris monitoring systems designed to detect the passage of metallic particles in fluid lines. The systems, which can be used in any pipe flow situation, are particularly suited to equipment applications where detecting metallic debris in the lubrication oil can provide early indication of component damage.

MetalSCAN technology enables the operator to plan maintenance actions, thus reducing lost revenue and repair costs. It also optimizes equipment availability and proactive planning for required maintenance.

Features

- 100% detection of ferromagnetic (Fe) and non-ferromagnetic (NFe) metal particles

- Easy to install

- Easy to interpret

- Rugged, solid-state with no moving parts

- Full function continuous Built-in-Test (BIT)

- Proven reliability in harsh machinery, high temperature and hazardous environments